Material handling equipment is critical in industries ranging from warehousing and manufacturing to construction and logistics. Choosing the right equipment can improve productivity, safety, and efficiency across operations. Here, we explore the most common types of material handling equipment, their primary functions, and where they excel.

1. Sit-Down Forklifts

Sit-down forklifts are one of the most versatile and widely used pieces of material handling equipment. They are designed for operators to sit comfortably while driving and lifting loads. As a Toyota forklift dealer, we always recommend their line of sit-down forklifts for their quality and efficiency. These forklifts come in two main types:

- Cushion Tire Forklifts: Best suited for indoor operations on smooth, level surfaces. They have smaller tires made of solid rubber, which makes them highly maneuverable in tight spaces such as warehouses.

- Pneumatic Tire Forklifts: Designed for outdoor use or rough surfaces, pneumatic forklifts have larger, air-filled tires that offer better traction and durability on uneven terrain.

Primary Uses: Loading and unloading trucks, moving palletized goods, and transporting heavy materials within warehouses, factories, and outdoor yards.

2. Stand-Up Forklifts

Stand-up forklifts are ideal for operations that require frequent on-and-off movement or working in narrow aisles. Operators stand upright while operating the equipment, offering greater visibility and maneuverability. Toyota also produces high-quality stand-up forklifts.

Primary Uses: Narrow aisle storage, quick load handling, and applications where efficiency in small spaces is critical.

3. Boom Lifts

Boom lifts provide elevated access for work at height. They are available in two primary configurations:

- Articulating Boom Lifts: These lifts feature multiple joints, allowing them to maneuver around obstacles and reach difficult areas.

- Telescopic Boom Lifts: Known for their straight, extendable arms, telescopic booms provide maximum horizontal and vertical reach.

Primary Uses: Maintenance work, construction, electrical repairs, and accessing tall structures safely.

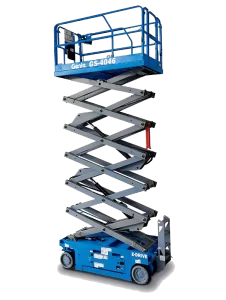

4. Scissor Lifts

Scissor lifts feature a stable, vertically rising platform supported by crisscrossing braces. They are a reliable solution for safely lifting personnel and equipment to moderate heights.

Primary Uses: Indoor and outdoor maintenance, inventory management, and tasks that require stable elevation, such as installing overhead fixtures.

5. Telehandlers

Telehandlers, or telescopic handlers, combine the lifting capabilities of forklifts with the reach of cranes. They feature extendable arms capable of lifting loads to greater heights and distances. Xtreme manufactures high-quality, heavy-duty telehandlers we often recommend to our customers looking for a more rugged design.

Primary Uses: Construction, agriculture, and material placement on elevated surfaces such as rooftops and scaffolding.

6. Sweepers and Scrubbers

Floor sweepers and scrubbers are essential for maintaining clean, safe, and debris-free workspaces.

- Sweepers: Use rotating brushes to collect dust and debris.

- Scrubbers: Combine water, cleaning solutions, and scrubbing pads to deep clean hard floors.

Primary Uses: Warehouses, manufacturing plants, and commercial facilities where cleanliness and safety are priorities.

7. Pallet Jacks

Pallet jacks are basic yet indispensable tools for moving palletized loads over short distances. They are available as manual or electric-powered models.

Primary Uses: Moving pallets in warehouses, stockrooms, and retail spaces.

8. Reach Trucks

Reach trucks are specialized forklifts designed for high stacking in narrow aisles. They feature extendable forks that allow operators to reach into racking systems.

Primary Uses: High-density warehouse storage, particularly in facilities with tall shelving.

9. Compact Forklifts

Compact forklifts are designed for operations in confined spaces. They offer the same lifting power as traditional forklifts but in a smaller, more agile frame. Mariotti is a popular brand for compact forklifts.

Primary Uses: Maneuvering in small warehouses, shipping containers, and other tight working environments.

10. Tow Tractors/Tuggers

Tow tractors, also known as tuggers, are designed to pull multiple carts or loads at once. They are commonly used in facilities with large-scale transportation needs.

Primary Uses: Line-side material delivery in manufacturing, baggage handling at airports, and efficient movement of goods in warehouses.

11. High-Capacity Forklifts

High-capacity forklifts are designed to lift and transport extremely heavy loads, typically ranging from 15,000 to over 100,000 pounds. Built for durability and performance, these forklifts feature robust frames, reinforced masts, and powerful engines (diesel, electric, or LPG) to operate efficiently in demanding environments.

Primary Uses: High-capacity forklifts are ideal for industries such as ports, steel manufacturing, construction, and heavy logistics, where oversized or dense loads like shipping containers, steel coils, and industrial machinery need to be moved safely and efficiently. Their advanced hydraulic systems, enhanced stability, and customizable attachments ensure precise handling and operational reliability.

Choosing the Right Material Handling Equipment

Selecting the right type of material handling equipment depends on factors such as the operating environment, load requirements, and specific application. By understanding the unique capabilities of each machine, businesses can improve efficiency, ensure worker safety, and streamline operations.

Contact Bell Forklift for expert advice on choosing the best equipment for your operation or to explore rental and purchase options. Our team is ready to help you find the perfect solution for your material handling needs!